Home |

Clinamen | Philosophy | Customer reviews | White paper | Pricing policy | Contact

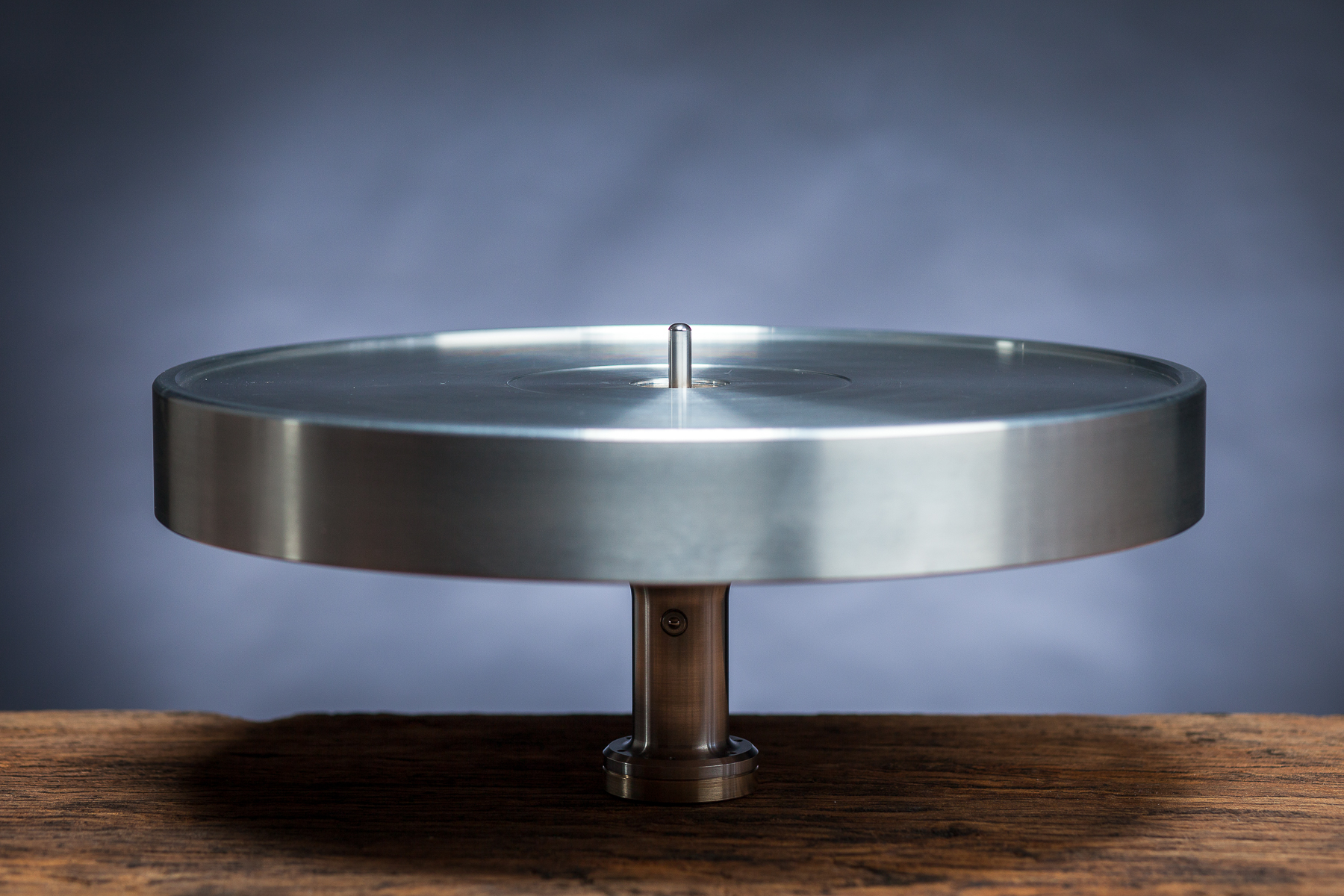

Spindle & platter custom Clinamen

Technical description of the Clinamen platter and spindle

We decided dedicate a page to a detailed and thorough description of the spindle/hub + platter we mount on our bull–wheel Clinamen CL12 turntables .

Clinamen Oversize 12 mm spindle

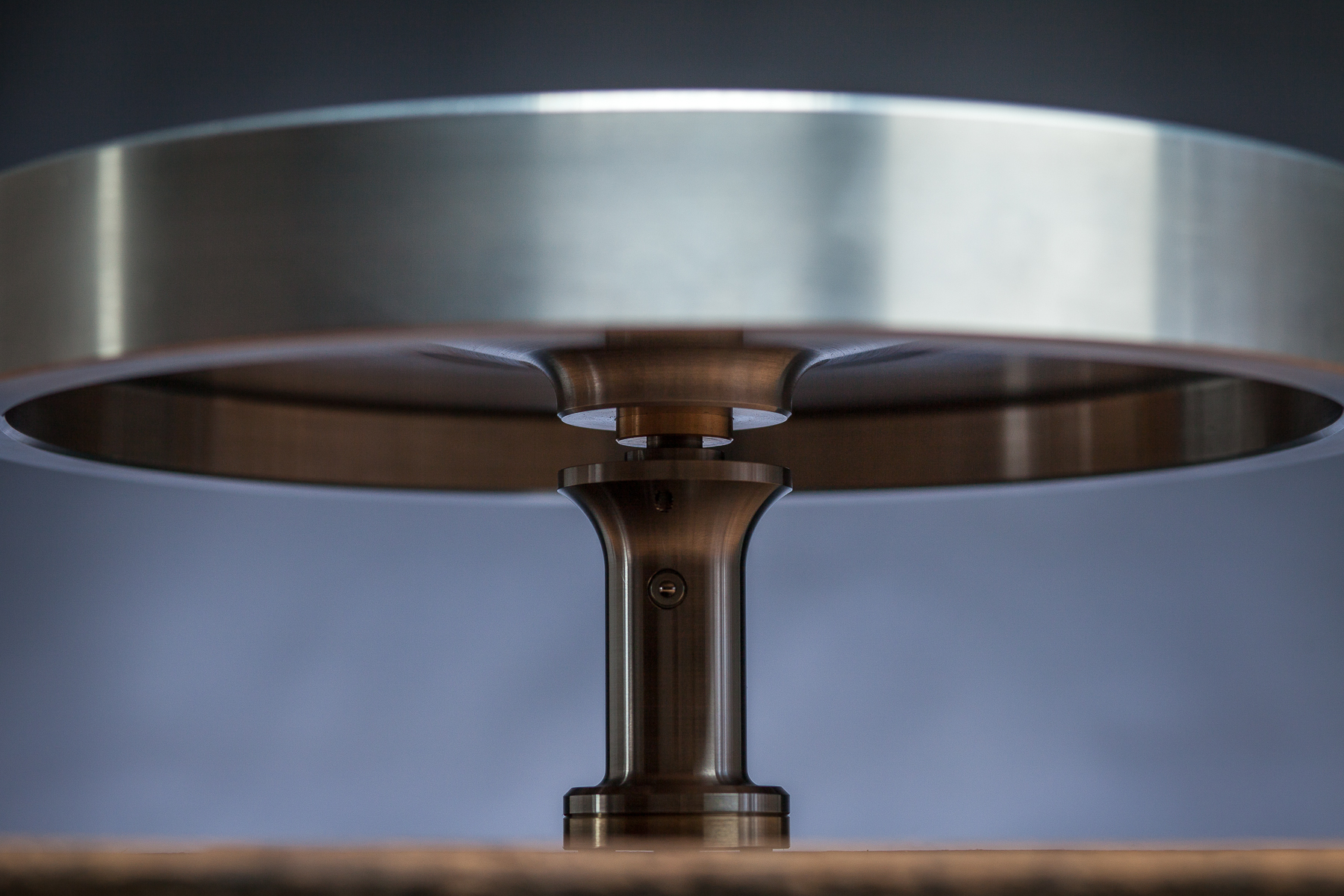

The spindle is our pride and joy. It is a masterpiece of mechanics, the result of over a year of study, several prototypes and listening tests. It enjoys a very generous size . Design and materials are top of the range. The diameter of the spindle his 12 mm. It is also longer in order to increase the mounting inter-axle for the bronze sintered bushes and to tolerate a greater overturning couple.

In the 2023 we change the bushing from sintered model to a CNC models made in Bronze-Tin Alloy. We change also the stainless steel thrust bearing sphere in a silicon nitride model

The materials used are:

- SAE 304 stainless steel for the hub

- CORRAX stainless steel for the spindle, heat treated for aging with subsequent adjustment and lapping, for the purpose of toughness both superficially and in the 50 HRC core.

- Carbide bit with anti-friction TiN coating (Titanium nitride submerged in metallic matrix) seated at the basis of the spindle.

- Bronze lower thrust bearing hosting a martensitic stainless steel sphere.

- Bronze-Tin alloy for bushing

The hub is made from SAE 304 stainless steel. Its solid structure is suitable to avoid vibrations and flections. It hosts two plain bearings mounted with interference.

The whole axial drive of the turntable is discharged vertically on an 8mm diameter sphere, which lies on a very big bronze thrust pad. The sphere is immersed in oil . Finally, at the basis of the thrust pad there is the housing for an O-Ring, which avoids any oozing of lubricating oil.

The coupling tolerances between hub and bearings are centesimal and the lubrication is assisted by a thin layer of oil. Once finished each hub is manually coupled with its hub; it is manually calibrated and it undergoes a 30 hours long pre-breaking in.

The hub, as it is built, is designed for a very long life span. Consider that the hub doesn’t lie directly on the stainless steel thrust bearing sphere, but a carbide bit is in between. After tens of years of usage you can replace the thrust pad or the sphere. Thanks to the carbide bit the hub will always be as new .

N.B.: in the final hub, the oiler visible in the body of the hub in the picture has been eliminated.

Clinamen ERGAL 7075 platter diameter 320 mm weight 5,0 Kg

Clinamen ERGAL 320mm Platter before the painting process

The platter as well, of course, is quite special. We have not been affected by the ‘quantity syndrome’, commonly used to impress in the HI-END world. We’ve avoided pointless oversizing and overweight platters. Physics tells us that it is not weight that matters but the angular momentum. In order to have a high angular momentum the mass must be distributed as much as possible on the external perimeter of the platter. If you look at how the flywheel of engines are made you will immediately realize what we mean.

The weight of the platter "is only" 5Kg, but what we did do is build a larger diameter platter of 320mm (300mm is the standard size) which concentrate the mass on the periphery. Thus the angular momentum is maximized with equal mass and this ensures great consistency in the platter rotation.

Another great advantage of our platter is its considerable thickness in the central part (17mm) which avoids:

- The platter to vibrate under external vibrational stimuli

- The bull wheel that rotates it from the bottom to excite its vibration (the ‘scraping’ noise that could be heard in the originals idler wheels platters when used without plastic mat has completely disappeared)

Our platters are ALL checked with the centesimal comparator to make sure that all the geometrical tolerances of concentricity and planarity are contained in a handful of hundredths .

Other gems of the platter are:

- Recess for the label of the vinyl

- Hosting recess for the mat

- Central insert made from bronze, with 3 degrees conical turning for zero tolerance coupling with the hub

- Metallic mat black or gold gloss painting

Please note: The spindle+ platter system is not sold as a separate unit from Clinamenaudio Turntable