Home |

Clinamen | Philosophy | Customer reviews | White paper | Pricing policy | Contact

"LUMINA" 300B

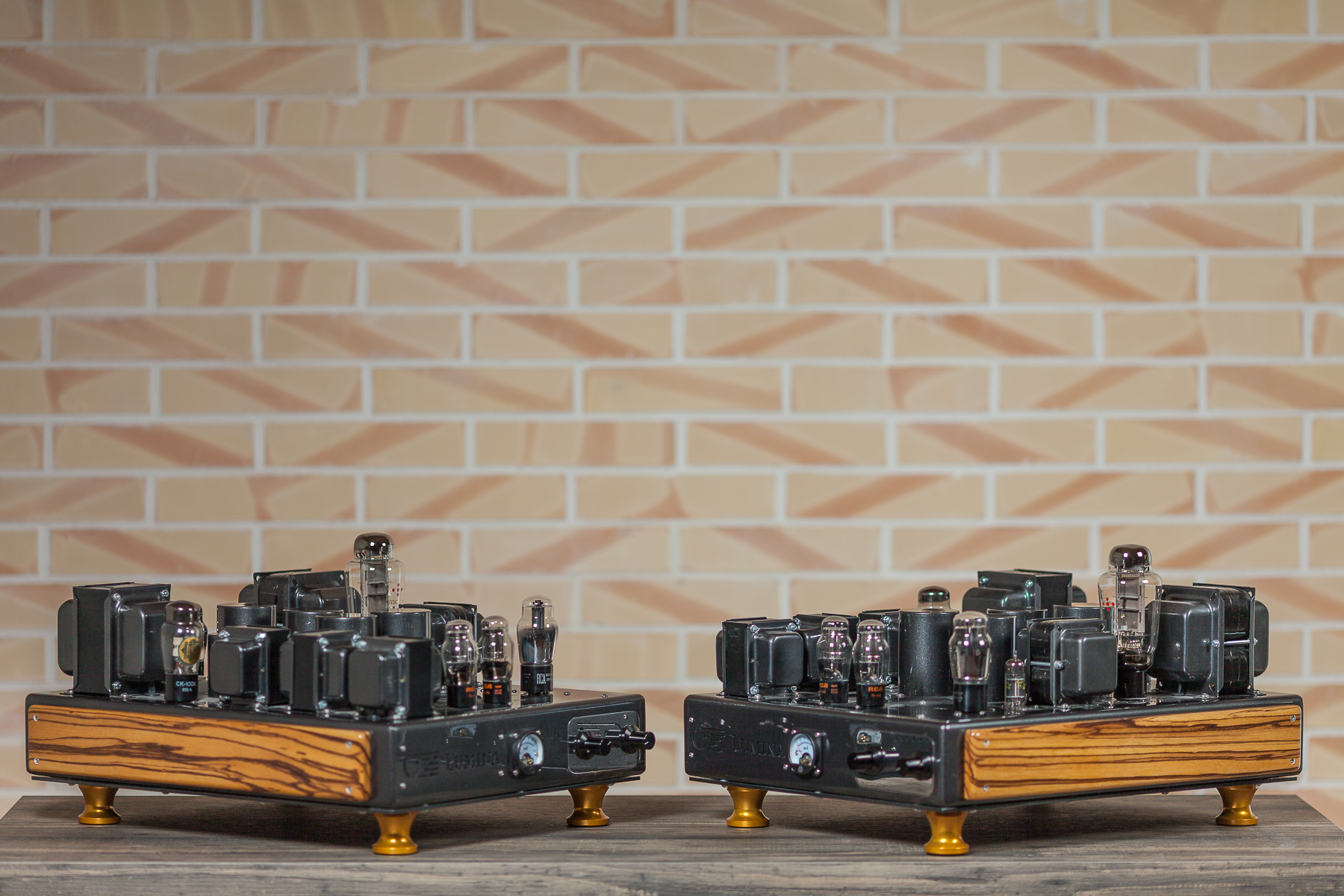

We have built the couple SN.1 of LUMINAs, reference amplifiers of Clinamen; and it is already at work in our latest Atelier.

They are monophonic integrated amplifiers with I.M.A. technology (Integrated Monoblock Amplifier), I.V.C. (Inductive Volume Control), electrolytic less, zero feedback, built around the final 300B TRUE MESH Emission Labs triode. Circuiting and materials used make this couple of amplifiers true Music machines, with a state of the art performance and in line with the Japanese giants.

We won’t repeat ourselves on the advantages of the I.M.A. and I.V.C. technologies, since we’ve already discussed them on another page.

Considerable dedication has been spent on the design, prototype, engineering and final realization of the Luminas and the result matches our expectations.

The circuit is an extremely elegant three-stage, where each component works in synergy with the others. The electrical performances achieved are all attained without any tricks, that is by exploiting the intrinsic linearity of the active elements, without any form of retroaction, which we call the ‘medicine’ needed to sick patients.

This curious comparison shows the concept of retroaction in the audio field. If we use it, we can afford to use non-linear components (both valves and coupling or output transformers) and then ‘linearize’ everything by using wide ranges of retroaction. Obviously this approach is convenient for the audio industries because they can use cheap components and they don’t need careful selection. Of course the ‘patient/amplifier’ will have excellent results thanks to the medicine ingested but it will essentially remain a sick patient with pathologies to be corrected (not cured). Clearly every medicine has collateral effects, which are often bigger than the symptoms they are meant to cure.

The Clinamen amplifiers are ‘healthy’ from the start, no pathologies whatsoever. This costs us a lot in financial terms because we search for the best available materials and then we match and select them at best. Thus our amplifiers do not need any medicine. When you buy ‘HI-END’ try and understand if behind the device there is actually the idea to build a Music machine. The best possible sound must be the design foundation; of course there must be some financial return but it must not be brutally maximized with the above mentioned tricks.

As we said, the first stage works in total synergy with the second. A 6N7 with paralleled sections to lower its internal impedance is directly coupled (no condenser, no transformer) with the 12B4 valve, which works as a driver for the final stage. The 6N7 is powered by stabilized tension supplied by two OD3 gas diodes, which stabilize the tension at 300 Volts. This makes the direct coupling with the next stage very stable; indeed the polarization of the 12B4 is strictly a function of the anodic tension of the 6N7.

Each valve is inserted in the circuit where its electrical characteristics are enhanced; the 6N7 supplies our tension gain, the 12B4 energetically drives the grid of the final stage which, on the contrary of what is normally believed, is not an easy load. For this reason the coupling between 12B4 and 300B is carried out through an interstage transformer with 1:1 ratio, aptly sized for the polarization current of the 12B4 and the tension swing necessary to bring the grid of the 300B in class A2. Yes, the Luminas, due to the power and refinement of the driver stage, can easily be pushed to class A2 (on the contrary of class A1, class A2 is characterized by a grid tension that becomes positive in relation with the cathode, as a consequence the grid of the final triode starts absorbing current). The class A2 is an obvious passage after class A1; indeed once the pilot signal reaches a peak value higher than the cathodic polarization tension, the grid starts absorbing current. A necessary requirement to go into A2 is to have a low impedance driver stage and inductive coupling, like in our case.

The class A2 must be considered as a power reserve; indeed the Luminas dispense 7 Watts in class A1 and reach up to 10 Watts RMS in A2, with a distortion lower than 5%. Obviously the distortion ratio grows in A2, but the clipping is quite soft, thus it is not a bother. If the Luminas are interfaced with at least 93 dB/W/m loudspeakers the power will always be exuberant for high dynamics listening.

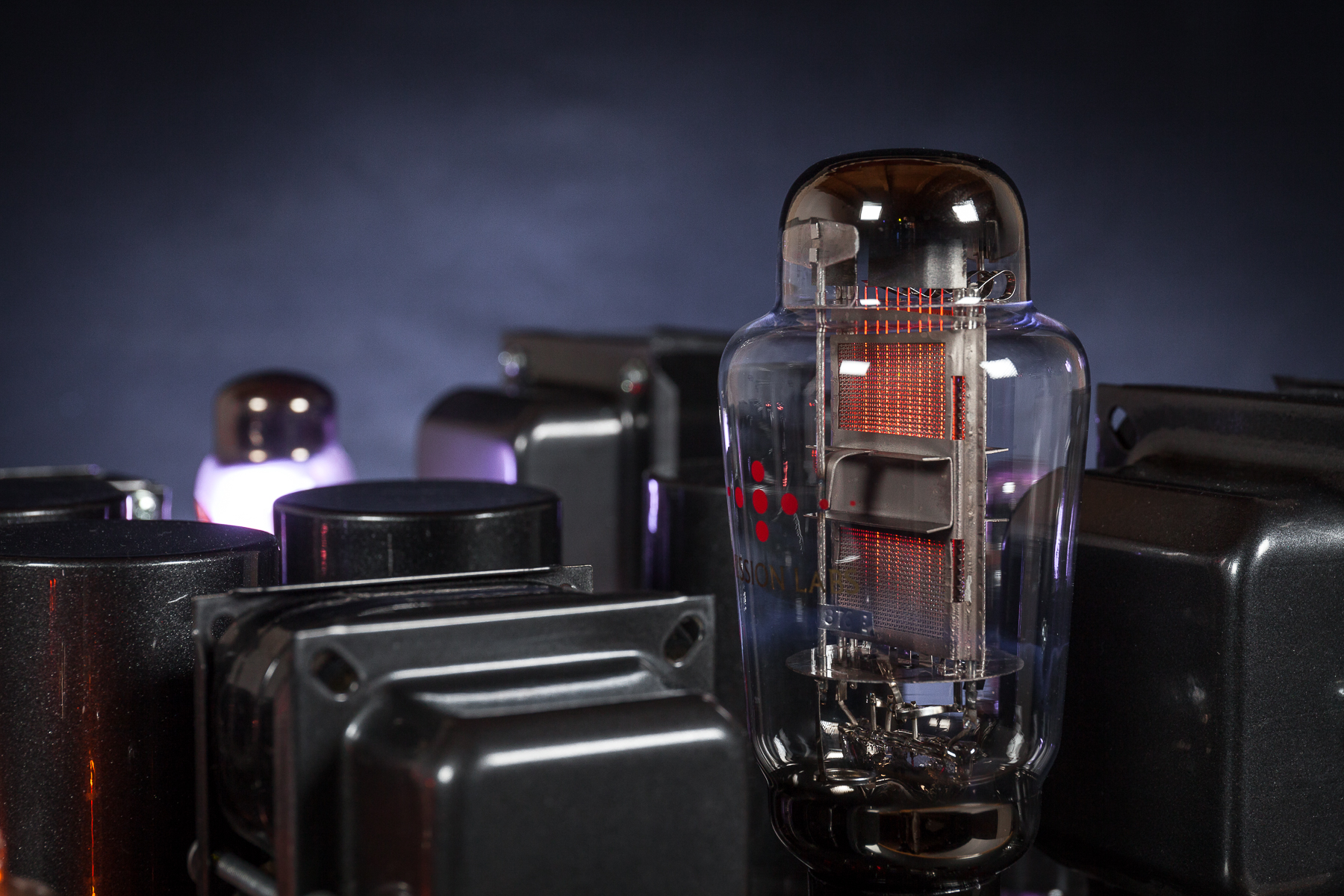

On the topic of the final stage, we can say that it is built around a 300B Emission Labs with a Mesh plate. The only company building proper Mesh plates is Emission Labs. This kind of plate is made of a metallic grid that allows to lower distortion and resonances. At the listening the triode can supply a well dimensioned scenic reproduction and a very fast bass full of harmonics. Such triode must be used cautiously, because the mesh plate tolerates a lower maximum power due to the reduced dispersing surface. But this is not an issue concerning the user, because we have designed and calculated the working point for the purpose of guaranteeing the tube a long life. The filament is on in continuous current and we’d like to spend a few words on the care and dedication that went into this power supplier.

Indeed we often hear talking about the 300B in non-enthusiastic terms; you must know, though, that it is very sensitive to the quality of the filament’s power supply and in order to build a good one no space or expense can be spared. We obviously did this. We used Schottky diodes and a refined filtering alternate current through a filter inductor. The latter is never used because it is a component that in order to supply 1.5 Ampere current and a reasonable inductance, at least 0.1H, can become almost as big as an output transformer.

A potentiometer has also been used for the balancing of the residual hum. In this circuit, which is basically crossed by the signal current, we used top of the range resistors: 10 Watts carbon Duelund. You won’t find on the market such quality resistor in the balancing circuit of the residual HUM; our tests show that their contribution to the sound is fundamental and this can be appreciated in consideration that they are on the path of the signal.

The bias of the final stage is obviously fixed and here, too, the power supply is very simple but refined. As well as the ‘usual’ fast diodes, we find inductive filtering and finally stabilization with gas discharge diodes. This stabilized tension is then supplied to the grid of the final valve through a multi-turn trimmer that allows to calibrate (in the factory) the resting current. The same resting current of the final stage is monitored by two backlit instruments placed on the front. They are not crossed by the signal current (or in a negligible percentage); indeed they are high internal impedance custom Clinamen.

The anodic power supply couldn’t be any less quality than the rest of the circuit and here, too, we spared no expenses. The alternate tension coming from the generous power supply transformer is straightened by a double ionized gas diode, the CK1006. It is as beautiful as fragile at the ignition; thus through a timed circuit the current needed for the circuit is required to the valve in two steps in time, for the purpose of bringing the valve in conduction gradually and without stress. The filtering is carried out through a double circuit with inductive filter cells and obviously the condensers used are not electrolytic but polypropylene oil filled. It is an expensive and bulky solution but it guarantees a very long life to the device, time consistency in its electrical and musical performances (electrolytics have a slow and continuous decay in time and they must be replaced after maximum 20 years), but most of all unrivalled speed of current supply and timbral neutrality.

The point to point wiringis made with Teflon insulated silver copper; even after 50 years the cable will keep its insulation, which cannot be said for PVC covered cables. The soldering is made with 4% Silver solder and the mass layout is optimized with a triple bus system, which guarantees a quietness that is unheard of. In actual fact the equation valve amplifier = noisy amplifier is completely wrong : each creation can either be made well or poorly; if the components layout and the masses wiring are made artfully a zero retroaction valve amplifier can have levels of quietness comparable to solid state creations.

Finally we’ll describe the frame, which is made of 4mm Anticorodal sheet, laser cut, bent and soldered and then professionally oven painted with Clinamen grey metalized glossy paint. Other colors are available on request for a small surcharge. On the front the name ‘Lumina’ and the Clinamen logo are EDM printed, lit from the inside through an opaline plastic material with high brightness LEDs. Two treble clefs and the name Lumina are cut out on the bottom of the device; as well as being decorative they supply ventilation. Finally we apply solid Zebrawood side walls, mirror polished, which give an impressive aesthetic enhancement as well as a touch of Italian design and style. Finally, each single screw is made of SAE 304 (stainless).

The external connections, input RCA and binding post, are made with high quality SHARK connectors. There are four RCA inputs and the input commuter, a top of the range Italian made component, is mounted right behind the clips to minimize the signal journey and it is activated by a brass extension stick

"We would like to point out that in general, and thus in the Luminas, too, we use valves that are little known to the audiophiles people. This is an absolute virtue and a clue that we look for something completely different from industrial Hi-End productions, which use the classic ECC series valve. We only use high trans-conductance triodes, only and exclusively NOS. We have a decent stock in our warehouse, enough to guarantee the replacement in all the devices sold. If you want to build a device without any compromise, the active device must be the heart of the project and it must be selected carefully, visualizing it in the circuit role it will have to play. Unfortunately we see many amplifiers with 300 B driven by ECC82 or even worse by ECC83 with resistive coupling (just to give an example). It is like racing in F1 with a sedan; you’ll finish the race, but with what performance?"

"We would like to point out that in this SN1 couple there are details that will be improved in the following serial numbers, such as the change of the socket from Bakelite CMC to JACKBANDS made of Teflon and tellurium copper; the spikes that arise as the device warms up will be suppressed because the outputs are short-circuited through the addition of a timing card; the addition of a second Omron timed relay, the new custom Clinamen front instruments, the millimetric repositioning of certain details and the use of new higher quality turret boards for internal wiring that we have already tested on the Blackstrat pre-phono"

TECHNICAL CHARACTERISTICS

- Integrated Monoblock Amplifiers (I.M.A.) with TRUE MESH EML 300B.

- 0 feedback design, lack of total and local feedback.

- 3 stages of signal without any condenser between them.

- Inductive volume control with 80% Nickel nucleus, with 16 positions to be selected via a commuter.

- Direct coupling between tension gain stage and driver stage.

- Transformer managed coupling between driver and final stage.

- Fixed bias for the 300B final triode, stabilized through gas-discharge tube.

- Rectification of anodic tension through CK1006 gas-discharge double diode.

- Anodic tension filtering through double inductive stage.

- 300B filaments supplied in DC with inductive filtering.

- Electrolytic less power supply (no electrolytics on the anodic power supplies). Polypropylene oil filled is used.

- Valves (for one channel): 1x6N7; 1x12B4A; 1x300B Mesh EML; 1xCK1006; 2xOD3; 1xOB3.

- Output power (RMS): 10 Watts with THD 5% (Class A2); 7.2 Watts with THD 2.1% (Class A1).

- Input sensitivity for the 10 Watts power: 0.45 Volts.

- 4 unbalanced RCA inputs (SHARK SCY 700), professional commuter made in Italy, mounted behind the back panel to minimize the signal route.

- One output with SHARK Binding Post at 8 Ohms.

- Starting automatized and timed via two Omron relays.

- Point to point handmade wiring, made with Teflon insulated silver cable and 4% Ag solder.

- JACKBAND valve socket made from pure virgin Teflon and pins made from a block of tellurium copper.

- Carbon resistors Kiwame (2 and 5 Watts) and 10 Watts Duelund.

- Frontal high impedance milliammeter (custom made) for monitoring the resting current of the 300B.

- Frame made of 4mm thick Anticorodal, dimensions 400 (l) x 500 (d) mm.

- Professional painting, metal Clinamen grey

- Bottom of the frame made of 5mm Anticorodal aluminium alloy, with friezes representing the name of the device and treble clefs.

- Backlit ‘LUMINA’ caption.

- Mirror polished Zebrawood sidewalls.

- Weight for each channel: 25 Kg.

- Price for the couple: on request.

FFT and Power measurement

Limit class A1 (148 Vpp). 5,3Wrms on 6,7 ohm. THD 1.79%

11Vp in class A2 (170Vpp). 7,1 Wrms on 6,7 ohm. THD 1,81%

22 Vp in class A2 (192Vpp). 9,12 Wrms on 6,7 ohm. THD 3,35%