Home |

Clinamen | Philosophy | Customer reviews | White paper | Pricing policy | Contact

Clinamen CL12 description

DESCRIPTION

As you have already read, Clinamenaudio firmly believes in the superiority of idler-wheel turntables. When it is implemented properly and with engineering know-how the heights of musicality and emotion that can be achieved with these devices are simply unreachable with a ‘belt’ transmission. The belt is an elasticated element and the coupling transmission always brings micro slips and irregularities. Even the modulations of the groove in the vinyl lead to small variations in speed. Our brain can perceive these phenomena no matter how small. The words that spring to mind after listening to a good bull-wheel turntable are: sense of rhythm, involvement and dynamics.

We, at Clinamenaudio, are committed to the idea of idler-wheel transmission and we have recognized the brilliance of the LENCO design. It is the only idler-wheel turntable where the pulley engages perpendicularly to the platter. Furthermore it has the possibility to continuously vary the speed, letting the pulley slide along the axis of the conic section motor. Nothing is simpler and more brilliant.

Thus we decided to offer two turntables which use the design of the LENCO’s transmission as a starting point. Physically the only things they have in common with the turntable is the motor and the tonearm that supports the bull-wheel. The rest is Clinamen custom.

Detail of the bull-wheel transmission in our Clinamen-Lenco Level 5 turntable

Many people have legitimately asked us: why not replace the motor, too? Because the rotor of the Lenco motor has a very high moment of inertia (a good 300 g•cmq) which is a value hardly achievable by a brushless motor; we consider this parameter very important indeed.

Let’s analyze in detail the problems that afflict the original Lenco turntables. We can list them as such:

Frame: the Lenco frame is unfortunately made from cheap printed 2mm metal plate. As well as being resonant, this is not sufficiently rigid, especially in the area of the spindle. Indeed there are differential flexures that compromise the reproduction quality.

Tonearm: the tonearm of the Lenco, despite having historical and collectors value, is unfortunately not suitable to guarantee a suitable tracking of your pick up. Barely damped, non-rigid, short and with too much play.

Plinth: the plinths supplied with the Lencos are simple frames of particleboard with veneer. Again, we are quite far from the necessary care that a no compromise bull-wheel device needs. In our turntables we use plinths made of a block of beech plywood.

Spindle: first of all we think that the original Lenco pivot is discreetly quality, but improvable. The housing of the thrust bearing sphere of the Lenco pivot is barely sufficient to support the weight of the heavy original platter of 3.3Kg. WE STRONGLY ADVISE AGAINST stacking platters. In the great majority of spindle we have inspected we have found that the plate under the steel thrust bearing sphere was deformed. Can you imagine what would happen with double the axial load! Furthermore the original spindle has often too much play with the brass bearing due to wear and tear. Another problem of the original spindle is the flexing of the hub. These concurrent issues cause imprecision in the reading and instability of the acoustic scene.

Platter: In a view of top quality the decent Lenco platter can be replaced by something heavier, more balanced, damped and most of all with greater momentum of the motion quantity. We can obtain this by increasing the diameter of the platter and concentrating the mass on the periphery. Furthermore by increasing the thickness of the platter it is possible to eliminate the ‘scraping’ noise caused by the pulley interacting with the original thin platter.

So we propose our turntable, the CL12. Here there is a Clinamenaudio plinth made of a block of beech plywood, Clinamen custom spindle and platter, top of the range tonearms supplied : Clearaudio Unify 12” . The CL12 has a bigger plinth designed to mount two tonearms. Also for CL12 we have provided for the option ♯ (diesis), which supplies the same products but with better ‘accessories’.

It is important for us to supply turntables with our accessories and designated tonearms because we think that in an analogic device everything works in synergy to reach the desired goal; by supplying each part of the turntable we can guarantee the result.

Example of frame plates BTF3 mounted on a Clinamen CL12 turntable

CL12

This is the top range of our idler-wheel turntables designed around the Lenco transmission system. In the CL12 the plinth beech plywood is made of 5 layers made from a block with a total thickness of 84 mm and a weight of 17 Kg. The diagram dimensions are quite imposing, 480x570mm because the plinth is able to support two tonearms, a 12” and a 9”.

The CL12, before 2023 was sold with the beautiful and good sound Thomas Shick 12" tonearm (cardanic bearing ). After 2022 is sold as standard with a Clearaudio Unify 12" mounted on a slate arm board. It is an excellent unipivot , not damped, tonearm at unrivalled value for money. Its best features are simplicity, fluidity of joints and extremely low building tolerances. Its mid-high range perfectly matches the natural path of the Clinamen Sound, making it possible to use MC cartridges with medium or medium/high compliance which we prefer.

Thomas Schick 12” tonearm used before 2023

We also supply a second hole with wood plug, for 9 " tonearms.

What makes this Clinamen CL12 idler-wheel turntable unique, though, is the use of a new dedicated platter and spindle. They are top of the range quality. The new platter we produce is made from ERGAL obtained by milling in order to have the centesimal control over geometrical dimensions. Its diameter is 320mm.

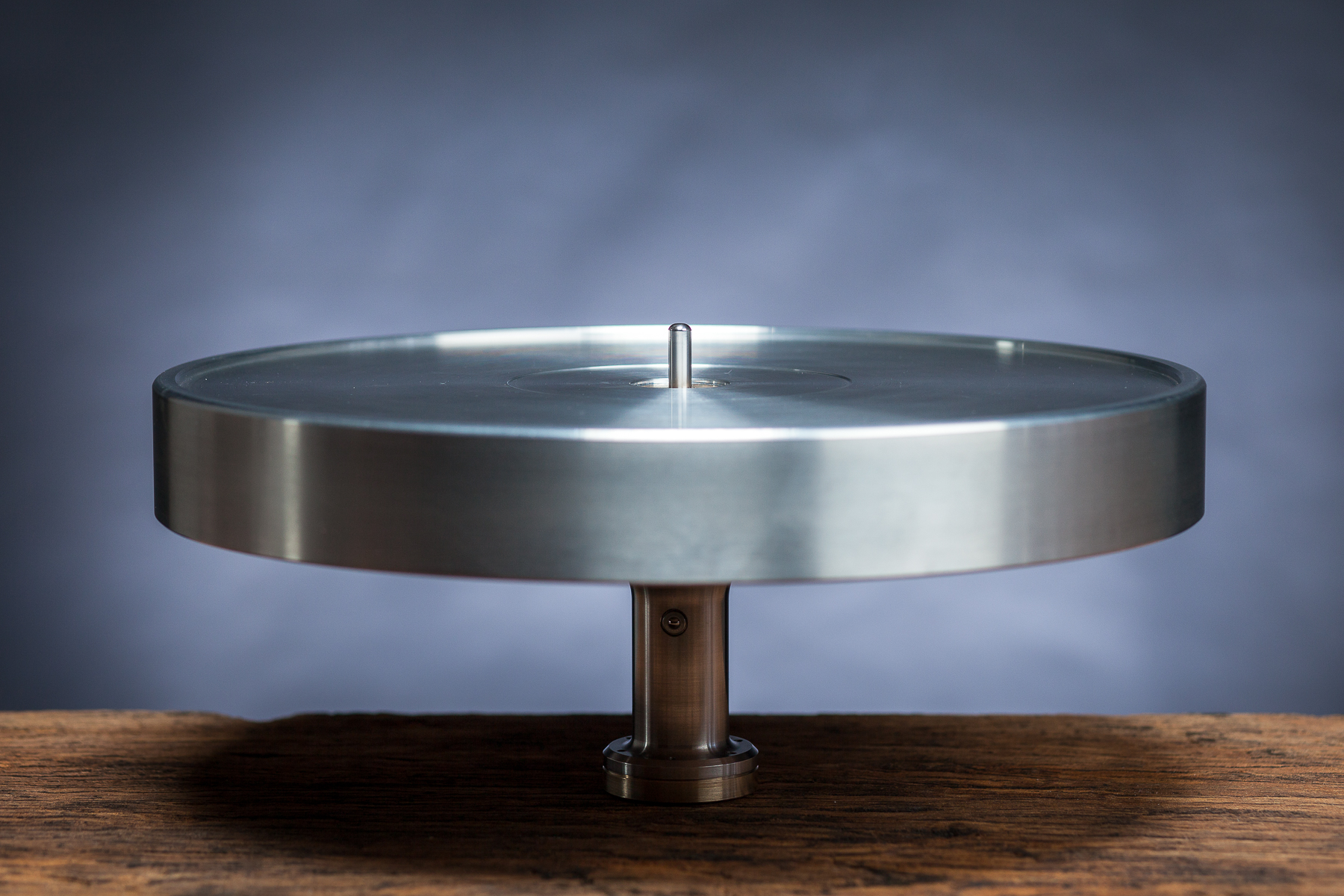

Clinamen platter and spindle before the surface finishing of the platter

The platter weighs 5,0 Kg. The advantages of this platter, as well as the obvious one of the greater mass, are:

- Much bigger diameter than standard – this means that the mass distributed on the periphery greatly increases the momentum of the quantity of motion (shuttlecock effect) supplying the platter with huge rotation constancy, much higher than what we’d hypothesize due to the mass increase.

- Greater thickness of the platter – this implies a greater insensitivity to the vibrations perceived but most of all to those generated by the rotation of the underlying bull-wheel (practically zero scraping effect).

The spindle is completely custom made; it is our own design and implementation. For its description please refer to the dedicated article. In brief we can tell you here that its diameter is 12mm . The length is also greater to offer better resistance to flection. The spindle is made from CORRAX stainless steel undergoes a thermal treatment to increase the surface hardness up to its core (against Martensitic quenching that works on the superficial layer). In its final end the pivot carries a carbide bit (tungsten carbide englobed in a metallic matrix) with anti-friction TiN coating, which interfaces it with the sphere ( silicon nitride after 2023) supporting the axial load. The thrust Pad is made from bronze with an oil drain pan.

Our 12mm custom spindle, an engineering masterpiece, implemented in the CL12

- System of Clinamenaudio mirror polished stainless steel platters BTF3

- Beech plywood Clinamenaudio plinth; dimensions 480 x 570 mm, 90 mm thickness hosting two tonearms. Weight 17 Kg.

- Matte lacquering of the plinth with color of choice without any additional cost.

- 12mm oversize Clinamen custom pivot

- Clinamen custom ERGAL platter, 320mm, choice of color between black or gold

- Clearaudio Unify 12" tonearm

- slate arm boards for Unify 12"

- Wood plug for the 9" tonearm hole

- 3mm cork Clinamen mat

- Coupling feet made from a full block of ERGAL

- Dimensions 570 x 480 x 90

- Total weight of the turntable 24Kg

- Price of the finished turntable 7450 Euros

- +150 Euros for gloss lacquering of the plinth

- Plexiglas 5mm dust cover available at 320 Euros

CL12 ♯ Turntable ( it looks identical to the L5, except for the mat and the clamp )

CL12 ♯

CL12 ♯ is a turntable identical to the CL12, but with a larger accessory supply which enhances greatly its performance. In CL12♯ we add:

- Clamp made from tone wood to the customer’s specification

- Spring De-coupling spring feet

CL12♯ turntable with its large accessories supply

Resonance wood clamps supplied as standard on CL12♯, type of wood to the customer’s specification

De-coupling spring feet supplied as standard on L5♯

The main features of the CL12 ♯ turntable are:

- System of Clinamenaudio BTF3 mirror polished stainless steel plates

- Clinamenaudio plinth made from a block of beech plywood; dimensions 480x570 mm and 84 mm thick hosting two tonearms. Weight 17 Kg.

- Matte lacquering of the plinth in a color of choice without any additional charge

- 12mm oversize Clinamenaudio custom pivot

- Clinamenaudio custom platter, diameter 320mm, made from ERGAL, 5,4 Kg weight, either black or gold

- Clearaudio Unify 12" tonearm

- Clinamenaudio clamp made from tone wood, 350 gr, type of wood to the customer’s specification

- One slate boards for tonearms mounting the Unify tonearm

- 5 mm Carbon fiber/cork mat

- Feet – choice between uncoupling spring or coupling made from brass

- Dimensions: 570x480x90

- Total weight of the turntable 24 Kg.

Price

8,300 Euros (+150 Euros for gloss lacquering of the plinth)

5mm transparent Plexiglas dust cover available for 320 Euros